GENERAL INFORMATION

Shelter direction

Shelter direction

Mobile Module for Multimedia Content Production and Distribution

The system essentially consists of the following Mobile Field Infrastructures:

NATO UEO2 Shelter = Mobile Control Room

The audio-visual distribution system has been designed to ensure maximum flexibility of use and integration with any broadcast-level or non-broadcast-level audio/video system, providing the Armed Forces with the means for the acquisition, recording, post-production, transport and dissemination of multimedia content.

The NATO UEO2 equipment shelter (also known as the ‘control room’) is the body responsible for controlling, coordinating and selecting the images displayed/recorded on the LED wall (big screen). It is the operations centre where video/audio production and all editing, titling and video effects creation takes place. Physically, the control room houses the console containing the video mixer, audio mixer, titling machine, monitors and intercoms.

Inside the control room shelter, the layout of the electronics on three rack columns was chosen based on operational requirements; the three areas, production, contribution and engineering, provide full access to all machines.

The LED wall and control room can be interconnected via fibre optic cable or, alternatively, to ensure compatibility with other systems, via analogue copper cable or SDI.

The control room shelter is the control, coordination and management centre for the LED wall displays. It performs technical checks in real time to verify that all image standards and levels are correct. It is also responsible for the audio components and all related sources: microphones, audio input and output lines, and audio signal distribution to all relevant parties.

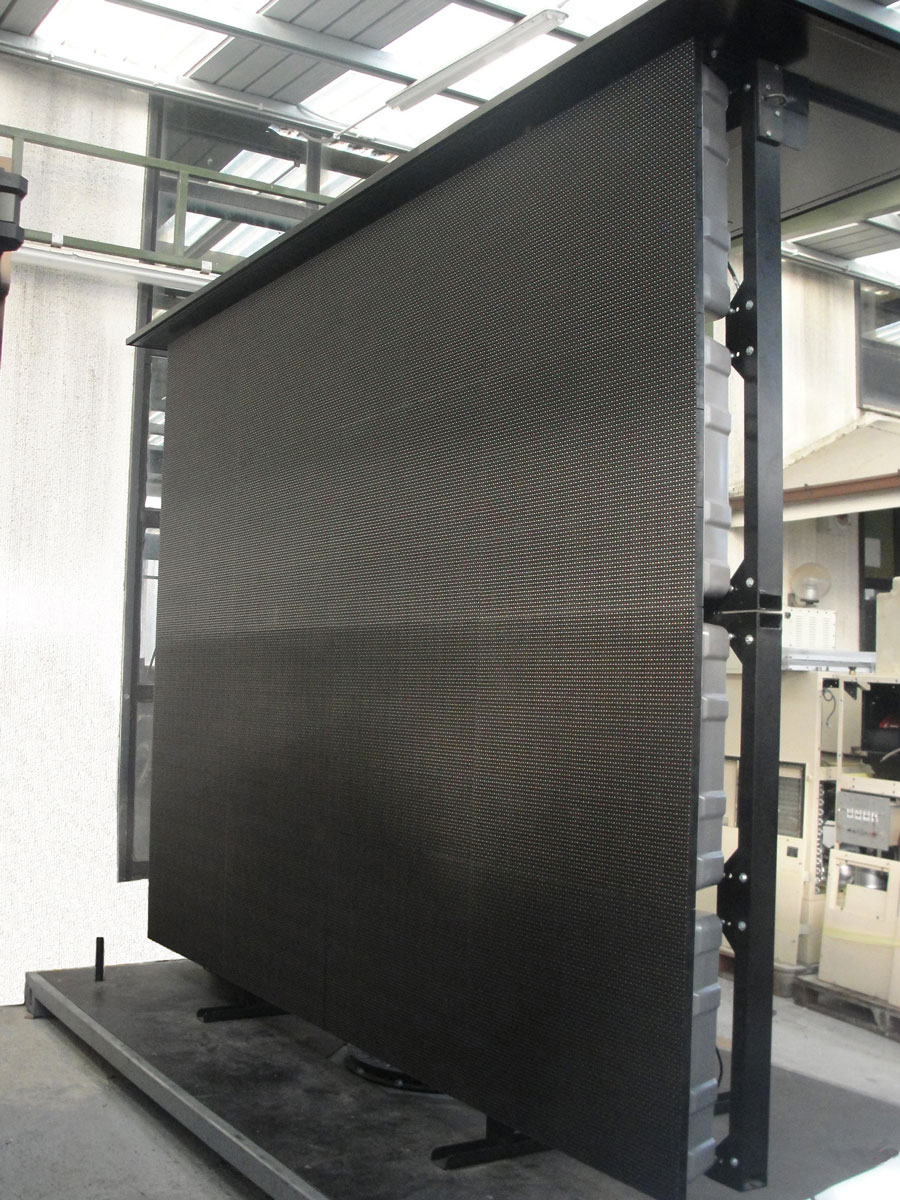

LED wall = Large LED screen

It consists of various modular LED panels which, in their final configuration, form a single maxi screen with a surface area of approximately 12m² (4:3 ratio) thanks to the use of metal supports and special brackets.

The large screen is housed on a base frame that matches the external dimensions of the base of the UEO2 Shelter with four corner blocks positioned at the vertices and joined together with extruded profiles. Four mechanical jacks will be positioned on the four corners in order to correctly level the assembly during deployment.

This solution allows the LED maxi screen and related accessories to be installed, transported, moved and deployed quickly. Using the hydraulic arm located in the centre of the base of the frame, the maxi screen can be rotated by approximately 90° and raised by approximately 2 metres.

Main features of the system:

- C130H/J aircraft in pressurised and non-pressurised compartments

- Shelter operating temperature: -32°C to +49°C;

- Ledwall operating temperature: -20°C to + 40°C;

- Wind: gusts up to 130 km/h

- Hail: up to 30 mm max diameter (according to ASTM1925-99)

- Salt fog 0.75 ng/m3

- Humidity 100% for 4 hours, 97% for 20 hours (according to ASTM1925-99)

- Rain > 40 mm/h with inclination up to 90°

- Easy transport by air, rail, road or ship, in order to ensure that the component can be moved quickly from the order of deployment;

- Appropriate construction criteria to ensure the survival of the system, the security of the information processed, and the safety of personnel.

- Preparedness to operate in an NBC environment;

- Protection of personnel health and safety to ensure liveability in accordance with non-military regulations in force and with reference to the ergonomic criteria provided for

- Autonomous air conditioning of operating environments;

- Operate in all weather and atmospheric conditions, even in adverse climatic environments such as desert, tropical, subpolar and alpine areas

- Limit/mask electromagnetic emissions from electronic components as much as possible;

- Comply with the electromagnetic compatibility standards provided for;

- Possess autonomous camouflage capabilities on the ground.

Advanced construction criteria in terms of environmental protection in order to limit any possible impact on the environment due to use.